Project Description

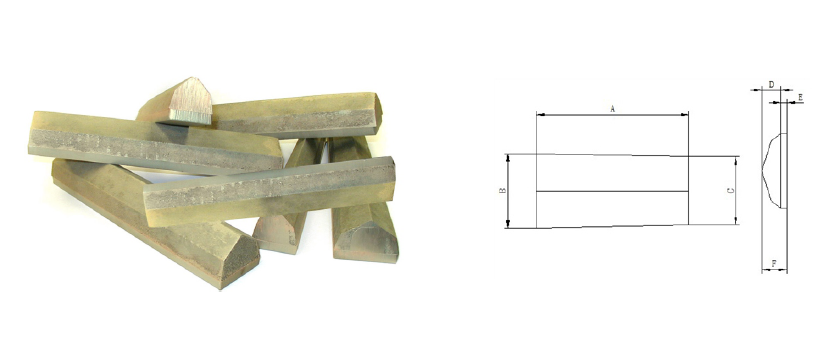

BURGOS “LAMINATED” GRIZZLY BARS 700 HB / 63 HRC

Burgos laminated 700 HB / 63 HRc Grizzly Bars are easy to use

Grizzly bars are available in width ranging from 75mm to 150mm and generally made in 305mm long sections with a number of different tapers offered to suit customer needs including mines, quarries and sinter process plants.

| Part NO. | Size(mm) | A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | Unit Weight(kgs) |

|---|---|---|---|---|---|---|---|

| GB10 | 305x150x137.5 | 305 | 150 | 137.5 | 38 | 12 | 13.5 |

| GB11 | 305x137.5x125 | 305 | 137.5 | 125 | 38 | 12 | 12.5 |

| GB12 | 305x125x112.5 | 305 | 125 | 112.5 | 38 | 12 | 11.2 |

| GB13 | 305x112.5x100 | 305 | 112.5 | 100 | 38 | 12 | 10.0 |

| GB14 | 305x100x87.5 | 305 | 100 | 87.5 | 38 | 12 | 8.8 |

| GB15 | 305x87.5x75 | 305 | 87.5 | 75 | 38 | 12 | 7.5 |

| GB16 | 305x75x62.5 | 305 | 75 | 62.5 | 38 | 12 | 6.3 |

| GB17 | 305x62.5x550 | 305 | 62.5 | 50 | 38 | 12 | 5.1 |

| GB18 | 305x151x141 | 305 | 151 | 141 | 38 | 12 | 13.8 |

| GB19 | 305x141x131 | 305 | 141 | 131 | 38 | 12 | 12.9 |

| GB20 | 305x131x122 | 305 | 131 | 122 | 38 | 12 | 11.9 |

| GB21 | 305x122x113 | 305 | 122 | 113 | 38 | 12 | 11.1 |

| GB22 | 305x113x103 | 305 | 113 | 103 | 38 | 12 | 10.1 |

| GB23 | 305x103x94 | 305 | 103 | 94 | 38 | 12 | 9.2 |

| GB24 | 305x94x84 | 305 | 94 | 84 | 38 | 12 | 8.3 |

| GB25 | 305x84x75 | 305 | 84 | 75 | 38 | 12 | 7.4 |

Burgos laminated 700 HB Wear-resistant Parts are the ideal solution for impact and high abrasion in the following industries:

- Earthmoving equipment and transhipment companies

- Cement plants

- Dredging industry

- Recycling industry

- Mineral processing industry

Burgos laminated 700 HB / 63 HRc Wear-resistant Parts benefits:

- Lower operating costs

- Longer Service when compared to conventional materials

- Increased production

- Improved product efficiency

- Increased equipment availability

Applications Burgos laminated 700 HB / 63 HRc Wear-resistant Parts:

- Chutes and liners

- Suction mouth dredging industry

- Protection of tunnelboring machines

- Shredder tips

- Protection dragheads dredging industry

- Protection earth moving equipment / shovels / buckets